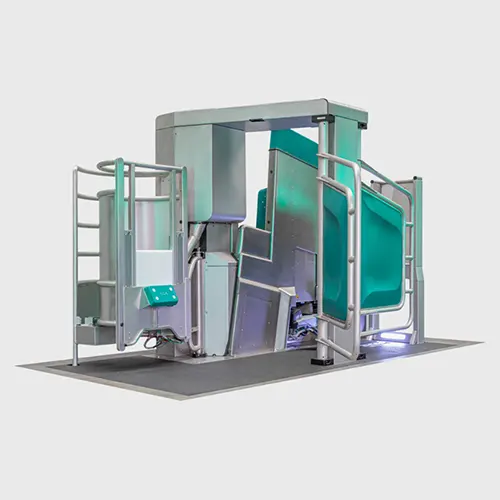

Intelligent, automated milking with the GEA’s DairyRobot R9500 (formerly GEA Monobox) offers premium cow comfort and increased productivity – all while freeing up your dairy time, so that you can focus on growing your operation.

The DairyRobot R9500 from GEA automates the entire management of your cows’ lactation. The design flexibility gives you a power to choose voluntary milking at times to suit your animals, or group milking with fixed milking times – with the benefit of no labour input in the process.

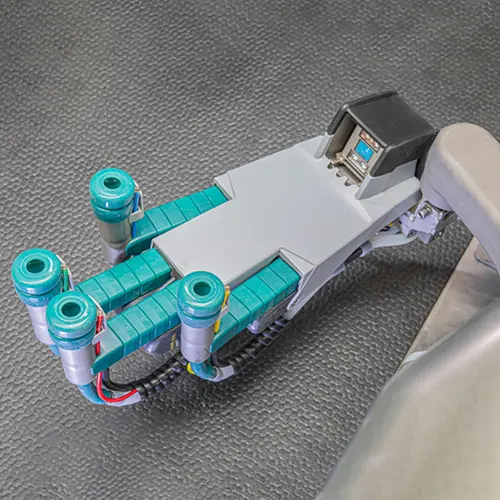

GEA’s In-Liner Everything technology is proven and trusted in performing each step of the milking process – from stimulation, to teat cleaning, to forestripping, to milk harvest and post-dipping – in a single attachment. This consistent, convenient and comfortable process, which is super-quick, all takes place within the teat cup and is key to harvesting premium quality milk.

Time/labour saving:

Enjoy all of the rewards of the highest quality milk production with none of the labour and minimal milking management time.Promotes udder health:

Sensors help facilitate early detection of mastitis. During milk flow, the optional GEA DairyMilk M6850 cell count classes sensor carefully monitors every udder quarter of each cow during each milking, without using any chemical consumables or reagents. Cell count analysis allows subclinical mastitis infections to be more accurately detected and treated early.Safe and easy use:

Unobstructed views of animals, easy udder and MilkRack access.Functional:

You can intervene freely in the milking process when you need to, whether to train new heifers, handle special needs cows, dry cows off, or more.Monitor milking/health:

Monitor real-time data on your milking parameters’ or animal health in read-at-a-glance graphs on your large touchscreen display.Cow comfort:

Wide entrance and exit gates ensure plenty of room for movement while the end frame guides cows gently into optimal attachment position. The MilkRack glides under the cow comfortably and quietly. A state-of-the-art 3D camera with Time-of-Flight (ToF) technology attaches the teatcup with absolute precision. When milking has ended, the hydroformed feed trough is covered to encourage your cow to exit quickly when the door is opened.Save space:

The DairyRobot R9500 is compact so it can be easily integrated into existing farm buildings or help save costs in new farm builds.Energy efficient:

Operate 24/7 with minimum use of consumables and energy. Connect up to four boxes to a single supply unit so they share one vacuum pump, compressor, milk and calf milk line, and tank connection. Less complexity, more efficiency.Easy ongoing management:

GEA FarmView keeps you up to date in real-time to ensure maximum performance and makes management of your milking robot easy.The system-monitoring software allows you optimise performance parameters while milking is taking place. This means you are always informed of any deviating values. And if you require a service diagnosis, a GEA service partner can access your system remotely.

Trusted service partners at McKnight Dairy Services:

When you choose a GEA milking robot from McKnight Dairy Services, we are always on hand for technical support and advice. From planning and installation to fine tuning the perfect milk production processes in your daily operation, we are here to lend a hand. You call, we respond – we are dedicated to ensuring the best for your dairy business.

Intelligent, automated milking with the GEA’s DairyRobot R9500 (formerly GEA Monobox) offers premium cow comfort and increased productivity – all while freeing up your dairy time, so that you can focus on growing your operation.